A pipe should not only pass industrial liquids easily from one location to another, but it must also be abrasion and corrosion-resistant. An ideal pipeline is easily installable, and must not leak. With HDPE pipes, you get all of these benefits.

HDPE pipes and fittings are rapidly becoming popular among engineers, contractors for various industrial applications, including energy, municipal, industrial, marine, mining, energy, geothermal, gas, oil, and agricultural applications.

HDPE pipes offer high strength, durability, and easy handling. The HDPE pipes, along with their numerous advantages, have diverse applications. They not only supply clean water to the industry’s doorsteps but they are cost-effective in comparison to pipes made from traditional materials

When researching possibilities for the pipe system of the business you are constructing, you must dig deep to discover a long-lasting material. In the commercial and industrial sectors, words have spread that when it comes to performance attributes, HDPE pipes and fittings perform brilliantly. As a result, it is not unusual that engineers, plumbers, and manufacturing industries in Pakistan use this material for enormous applications in gas, oil, mining, maritime, and agricultural functions.

Key characteristics include:

The pipes that supply water and chemicals to your commercial and industrial sectors may not be apparent. However, when something goes wrong with HDPE, it ensures transparency.

You can invest in HDPE pipes to avoid costly and perhaps dangerous plumbing breaks. The construction staff will also appreciate your decision. After all, these pipes are lightweight.

They do not even require heavy lifting equipment and do not require additional time or money to transfer over rough terrain. Because of the material’s adaptability, the installation of HDPE pipes is more effective than other pipes.

You may not consider it a priority, but you should examine the sustainability of every item used in your office and building base. You want a long-lasting seamless pipe system, but you also want something that will not harm the environment.

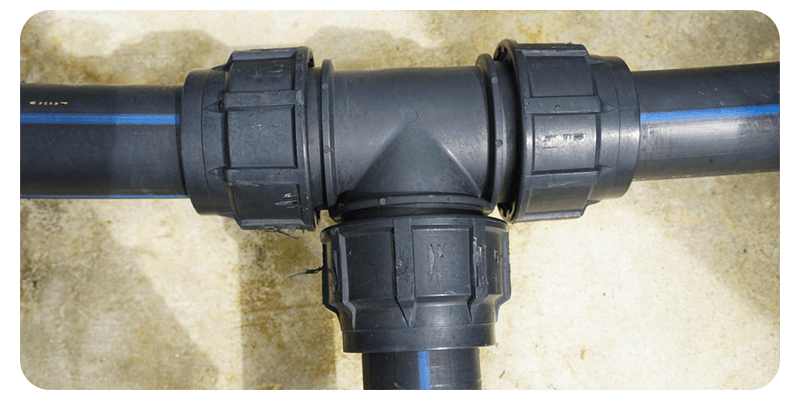

The best factor about HDPE pipes is how simply we can weld them together. If the installers complete their work correctly, there should be no leaks in the system. Because the pipes are durable, they will survive for many years, and the sustainable system you have chosen will provide you with long-term reliability that no other material can.

Key points that define HDPE pipes are:

The most desired feature of high-density polyethene pipes may need to be mentioned. Therefore, they provide greater, smooth fluid movement with minimal drag. There is less turbulence as the flow rate increases. Smooth flow in HDPE pipes avoids pitting and scaling and extends the life of the plumbing system as a whole.

PVC Pipes produced in recent decades replace heavy materials such as steel and other costly metals. Obviously, plastic is lightweight, but HDPE has other benefits such as dependability, adaptability, and sustainability.

Although HDPE pipe is commonly projected to last 50 years, it is more likely to have a life expectancy of 100 years. PIPA (Plastics Industry Pipe Association) and the Plastic Pipe Institute (PPI) have published technical white papers on the design life of HDPE pipes. The PIPA study is titled “Life Expectancy for Plastics Pipes,” and it states that due to the fifty-year stress regression data, people incorrectly believe that the life expectancy of plastic pipe systems is just fifty years.

In fact, these pipe systems may survive for 100 years or more. PE pipes and fittings were first introduced in Australia in the mid-1900s, primarily for irrigation or water delivery and gas, fuel, and other industrial purposes. The usage of these 50 years gives rise to the misconception that it indicates a 50-year pipe life. We cannot estimate the actual life of HDPE pipe systems, but it can be more than 100 years before extensive repair is required.

PVC is a durable vinyl polymer, whereas HDPE is a petroleum-based polyethene thermoplastic. Both pipes are resistant to high temperatures. HDPE is more durable when evaluating failure ratings when subjected to rain, stress, wind, heat, or cold.

Both HDPE and PEX are polyethene (PE); however, it is important not to mistake these two very different materials because of their distinct qualities.

It is simpler than you think to learn how to use HDPE to design and construct pipe systems. Contractors and installers may teach their teams to use this precious material in new and existing applications by utilising HDPE installation training services.

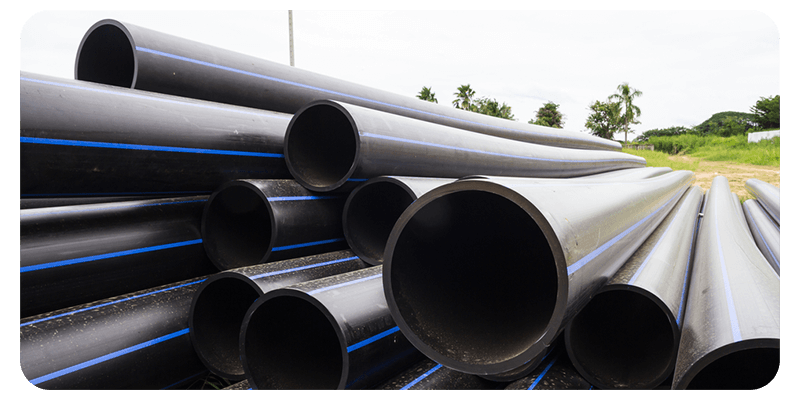

Manufacturers of HDPE pipes fulfil the stringent requirements of a wide range of commercial and industrial projects. HDPE pipes are ideal for laying in steep and uneven terrains because of their superior durability. Their adaptability allows them to follow the contours of the land.

Aside from durability, HDPE pipes feature low specific weight, splendid chemical resistance, unblemished weld-ability, outstanding abrasion resistance, and strong weathering resistance.

Adamjee Dura Built (Private) Limited was incorporated in 1984. We are the market front-runner due to our winning edge in quality control, product range, prompt and efficient service.

Since the 80s, we have been manufacturing quality electrical trunking, uPVC pipe, flexible pipe & fittings, uPVC electrical conduits, and have diversified to capture the water pipe market with DuraSDR, Dura Sch40, DuraTubewell, DuraPE and DuraFitting.