Description

HDPE Pipes and Fittings Manufacturer in Pakistan

Our HDPE Pipe manufacturer ensure superb abrasion and impactful resistance in DuraPE which makes it a perfect choice in order to be used for water supply/distribution systems, compressed air, chemicals, and hazardous wastes, slurries, mining, and irrigation. Our (HDPE Pipes) High-Density Polyethylene pipes has a long-life span and toughness qualities, making it an ideal selection for remote areas usage.

Major Areas of Application

* Water supply system

* Sewerage, drainage & industrial applications

* Irrigation, farming and tubewell applications

* Potable water distribution system

* Telecommunication industry for cable protection

* Construction industry

* Gas & oil transmission

* Power plants & chemical industry

Advantages of HDPE Pipes & Fittings

Following are the advantages of HDPE Pipes that accommodate:

*Hygienically safe

* Smooth flow guaranteed

* Low maintenance & operational cost

* Resistant to extreme weather conditions

* Lightweight which makes it easy to install

* Free from leakage, corrosion and chemical reaction

* Long life

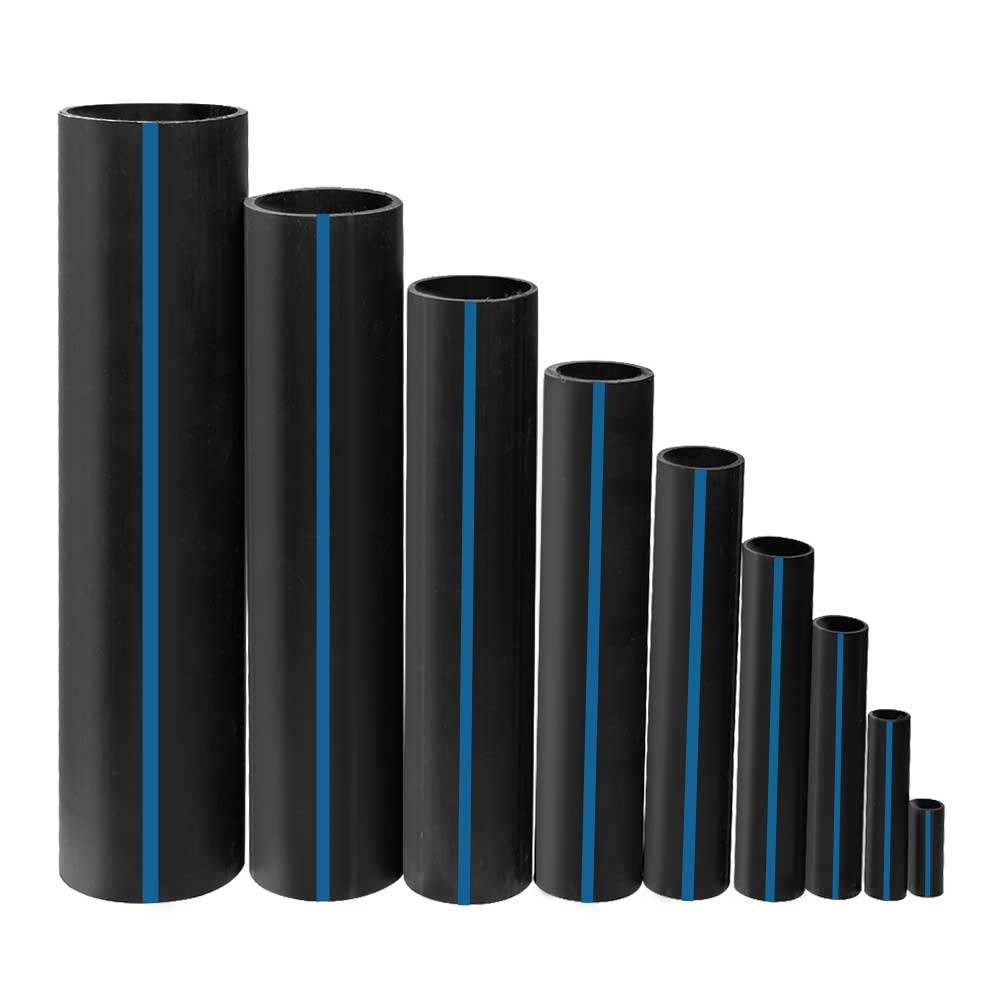

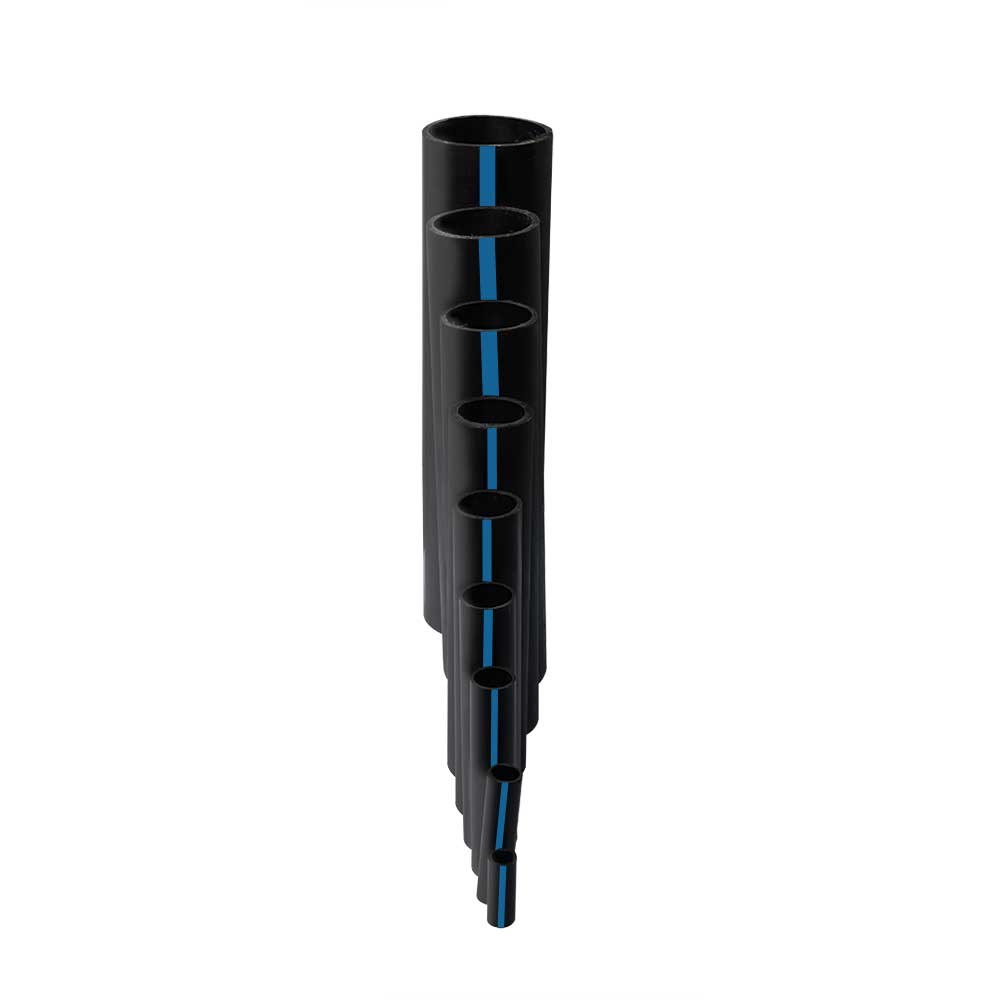

Available Range

* 20mm to 75mm in coils of 100 & 150 meters

* 90mm in coils of 100 meters

* 75mm to 125mm in a standard length of 12 meters

Colour Range

* Black with Blue strips.

HDPE Pipes Specifications

Standard ISO: 4427, DIN 8074/8075

| Size (mm) |

Outer Diameter (mm) |

WALL THICKNESS (mm) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| SDR-9 (PN-20) | SDR-11 (PN-16) | SDR-13.6 (PN-12.5) | SDR-17 (PN-10) | SDR-21 (PN-8) | |||||||

| Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | ||

| 20 | 20.0~20.3 | 2.3 | 2.8 | 1.9 | 2.3 | 1.8 | 2.2 | – | – | – | – |

| 25 | 25.0~25.3 | 2.8 | 3.3 | 2.3 | 2.8 | 1.9 | 2.3 | 1.8 | 2.2 | – | – |

| 32 | 32.0~32.3 | 3.6 | 4.2 | 2.9 | 3.4 | 2.4 | 2.9 | 1.9 | 2.3 | – | – |

| 40 | 40.0~40.4 | 4.5 | 5.2 | 3.7 | 4.3 | 3.0 | 3.5 | 2.4 | 2.9 | 1.9 | 2.3 |

| 50 | 50.0~50.5 | 5.6 | 6.4 | 4.6 | 5.3 | 3.7 | 4.3 | 3.0 | 3.5 | 2.4 | 2.9 |

| 63 | 63.0~63.6 | 7.1 | 7.6 | 5.8 | 6.6 | 4.7 | 5.5 | 3.8 | 4.4 | 3.0 | 3.5 |

| 75 | 75.0~75.7 | 8.4 | 9.5 | 6.8 | 7.7 | 5.6 | 6.4 | 4.5 | 5.2 | 3.6 | 4.2 |

| 90 | 90.0~90.9 | 10.1 | 11.4 | 8.2 | 9.3 | 6.7 | 7.6 | 5.4 | 6.2 | 4.3 | 5.0 |

| 110 | 110.0~111.0 | 12.3 | 13.8 | 10.0 | 11.2 | 8.1 | 9.2 | 6.6 | 7.5 | 5.3 | 6.1 |

| 125 | 125.0~126.2 | 14.0 | 15.6 | 11.4 | 12.8 | 9.2 | 10.4 | 7.4 | 8.4 | 6.0 | 6.8 |